Mechanical keyboard PCBs typically come in two forms: hotswap and solder. Solder PCBs require a specialized tool, wire, and a basic understanding of how to solder components together.

Hotswap PCBs allow users to plug and play with their mechanical keyboard switches. No soldering experience or equipment is required; users line up a switch with its respective socket and carefully push it in.

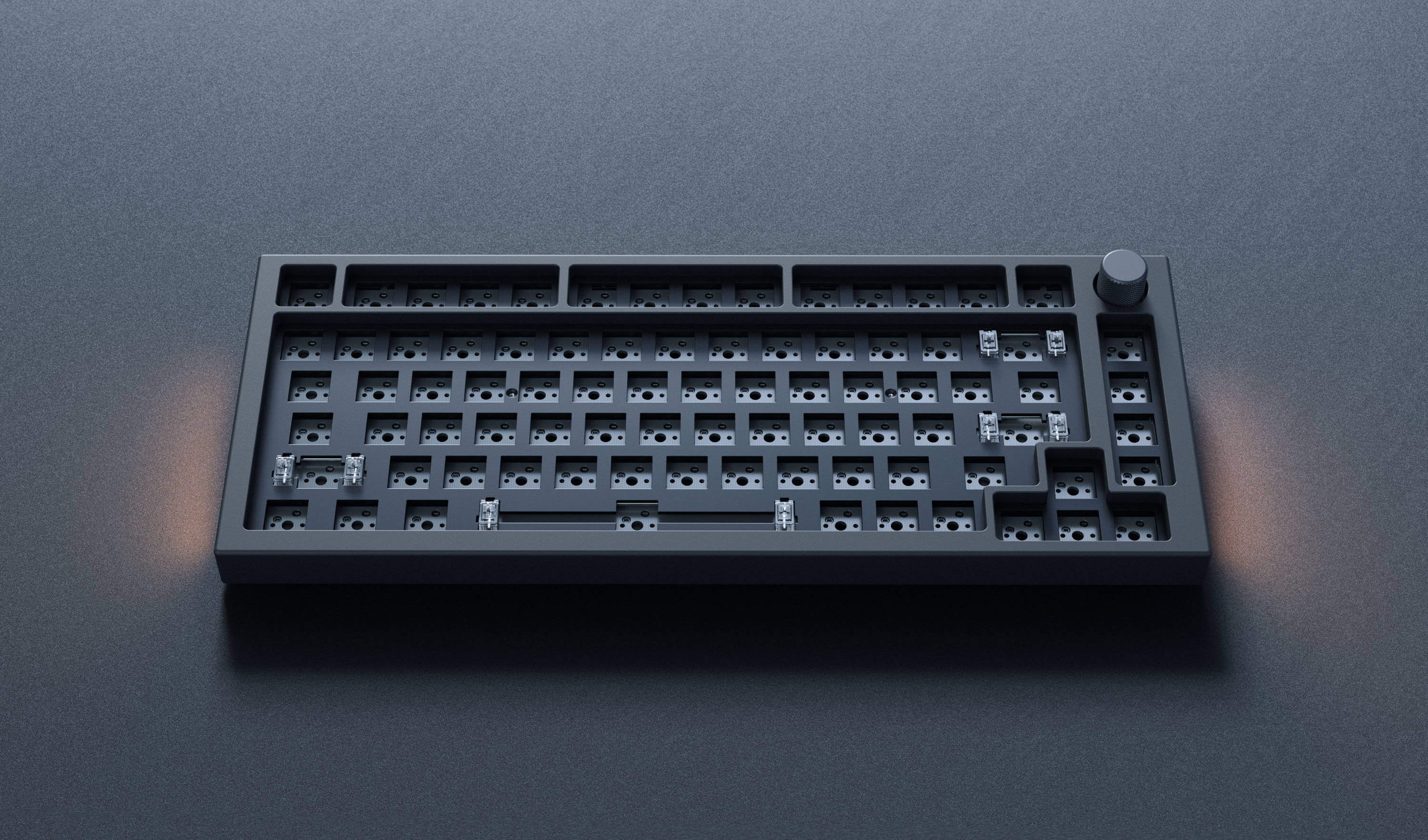

Our keyboards, including the GMMK and GMMK PRO, come with modular, hotswap sockets that allow for a solder-free installation process.

However, this process can be a little more intensive than how it sounds. While the margin for error is much less than soldering, there are still some key things to remember before slotting in your switches.